As energy systems evolve, the demand for intelligent, connected infrastructure continues to rise. In this context, current transformers are more than just passive components, they are essential enablers of digital metering systems.

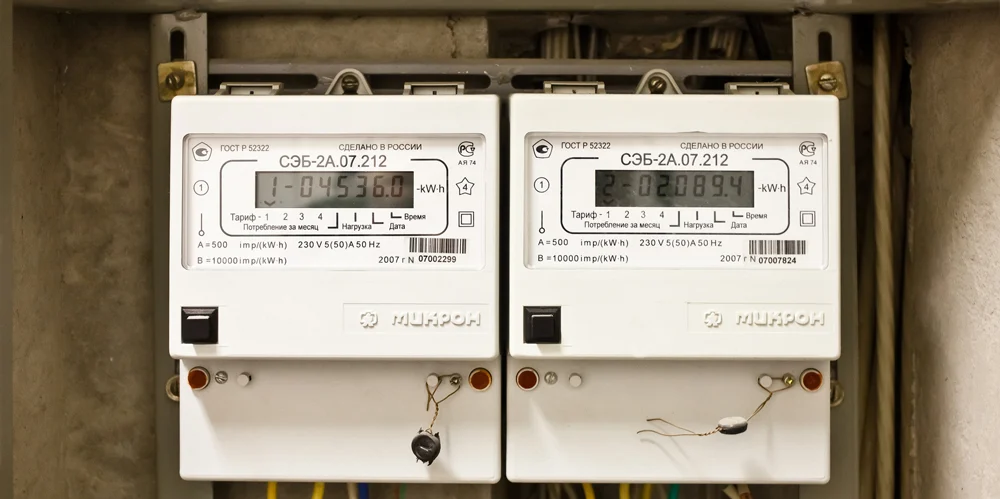

Today’s energy meters often come equipped with advanced analytics and communication features such as Modbus. For these systems to function accurately, they must receive reliable input signals, which is exactly where current transformers come in. By ensuring consistent and accurate current scaling, transformers allow energy meters to collect high-quality data that can be transmitted, stored, and analysed remotely.

This level of integration is particularly valuable in large commercial or industrial setups where facilities span multiple locations. In such settings, remote monitoring and real-time analysis become critical to ensure operational efficiency, manage load distribution, and avoid costly downtime. A well-chosen current transformer supports these capabilities by maintaining accuracy and stability under varying load conditions.

Importance of Calibration and Maintenance

While selecting the right transformer is crucial, maintaining it over time is equally important. Even the highest quality current transformer can drift in accuracy if not regularly calibrated or checked for wear and tear.

Calibration ensures that the transformer continues to meet its specified accuracy class and remains aligned with the metering device it supports. In high-stakes environments such as utility metering or regulatory compliance reporting, periodic calibration is not just a best practice but often a legal requirement.

Physical inspection is also necessary to check for signs of degradation such as cracked insulation, rust on terminals, or poor mounting. Environmental factors, mechanical stress, and thermal cycling can all impact a current transformer’s performance over time.

To maintain measurement integrity, it’s recommended to schedule maintenance checks annually or in accordance with the manufacturer’s guidelines. This ensures consistent data quality and extends the operational lifespan of the equipment.

Supporting Energy Efficiency Goals

With growing emphasis on sustainability and energy conservation, organisations are under pressure to monitor and reduce their consumption. Current transformers play a behind the scenes but vital role in these efforts.

By providing real-time insight into current flow, transformers help identify energy-intensive equipment, periods of peak usage, and sources of wastage. This data allows facility managers to optimize load profiles, implement energy-saving strategies, and justify investments in more efficient machinery or renewable energy integration.

Reliable current measurements help demonstrate compliance with environmental benchmarks and strengthen an organisation’s sustainability credentials.

In this sense, CTs don’t just support the technical aspects of energy monitoring and they also contribute to corporate environmental and governance goals, helping businesses align with global energy efficiency targets.

Understand the Installation Environment

The first and most crucial factor to consider is the physical and operational environment where the transformer will be installed. Environmental conditions can impact the accuracy, lifespan, and safety of the device.

Indoor vs Outdoor Setup

Start by identifying whether the installation will be indoors or outdoors. Outdoor environments may require enclosures or weatherproof designs to shield the transformer from rain, dust, and temperature extremes. On the other hand, indoor installations may still face challenges like humidity or lack of ventilation.

Temperature and Humidity Ranges

Always check the ambient temperature range where the transformer will operate. Excessive heat can cause insulation degradation, while extreme cold may affect its responsiveness. Similarly, high humidity could lead to moisture ingress, risking insulation breakdown or short circuits.

Mounting Space and Accessibility

Ensure there is enough physical space for proper installation and future maintenance. Tight or awkward locations can result in poor installation, incorrect positioning, or difficulties during regular inspections. Wall-mounted or busbar-mounted options may vary in design dimensions, so review compatibility with the layout.

Know the Types and Benefits of Current Transformers

While selecting a transformer, understanding the types and benefits of current transformers helps to make an informed decision. There are various construction types such as Encapsulated, three phase and split-core. Each suited for specific scenarios. Split-core variants, for example, allow installation without disconnecting existing wiring, making them ideal for retrofitting.

Additionally, benefits like electrical isolation, improved safety, and support for a wide range of current levels make them indispensable in any energy metering setup. By knowing your system’s needs and understanding each type’s advantages, you can choose the right fit that balances cost, performance, and installation ease.

Final Considerations for Selecting CTs

To summarise the selection process:

- Define your application: Is it for metering, protection, or both?

- Know your load: What is the maximum expected current, and how variable is it?

- Verify compatibility: Does the CT match the input requirements of your meter?

- Check installation requirements: Will it be retrofitted or part of a new system?

- Prioritise accuracy: Are there regulatory or billing-related accuracy requirements?

- Plan for the long term: Think about future scalability, maintenance, and digital integration.

Choosing the right current transformers may take some research and consultation, but the result is a more reliable, accurate, and future-ready energy monitoring system.