Finding reliable MWM parts wholesale suppliers can make or break your industrial operations. The wrong supplier choice costs thousands in downtime, while the right partnership ensures seamless engine performance and competitive pricing.

This comprehensive guide reveals proven strategies for identifying trustworthy suppliers, evaluating their credentials, and building profitable long-term relationships. You’ll discover essential verification methods that separate professional suppliers from unreliable vendors, plus insider techniques for negotiating favorable wholesale terms.

Learn how to assess supplier financial stability, implement quality assurance protocols, and avoid costly procurement mistakes. Whether you’re sourcing for maintenance operations or major rebuilds, these actionable insights will transform your parts procurement strategy and secure your supply chain success.

Understanding MWM Engine Components

Master the fundamentals of MWM parts identification and specifications to make informed wholesale purchasing decisions that align with your operational requirements and quality standards.

Types of MWM Engine Parts Available

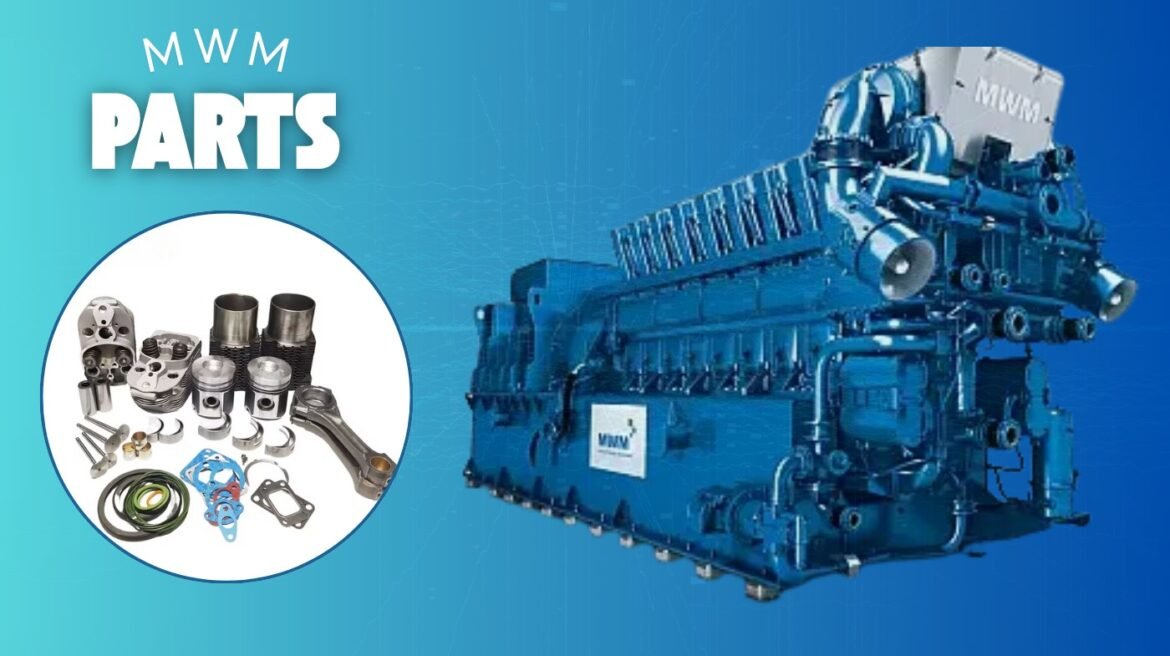

MWM engines require diverse component categories spanning fuel injection systems, cooling components, electrical parts, and mechanical assemblies. Wholesale suppliers typically stock cylinder heads, pistons, gaskets, filters, and specialized electronic control modules.

Understanding part classifications helps streamline procurement processes and ensures compatibility across different MWM engine models. Engine rebuilds demand comprehensive part inventories including crankshafts, connecting rods, and bearing assemblies.

Maintenance operations require regular replacement items such as oil filters, air cleaners, and fuel system components. Preventive maintenance schedules dictate seasonal purchasing patterns for wholesale buyers.

Quality Standards and Certifications

Authentic MWM components meet stringent manufacturing specifications established by the original equipment manufacturer. Certified parts undergo rigorous testing protocols, ensuring dimensional accuracy, material composition, and performance characteristics align with factory standards.

Quality certifications validate supplier commitment to excellence. Aftermarket alternatives require careful evaluation of manufacturing processes and quality control systems.

Reputable suppliers provide detailed specifications, testing documentation demonstrating product reliability. Third-party certifications from recognized testing organizations add credibility to aftermarket offerings.

OEM vs Aftermarket Considerations

Original equipment manufacturer parts guarantee perfect compatibility and performance standards, but often command premium pricing in wholesale markets. OEM components provide peace of mind through factory backing and comprehensive support coverage.

Budget considerations may necessitate exploring aftermarket alternatives for non-critical applications. Aftermarket suppliers offer cost-effective solutions without compromising essential functionality for many MWM applications.

Quality aftermarket manufacturers invest heavily in research and development to match OEM specifications while providing competitive pricing structures for wholesale buyers.

Identifying Reputable Wholesale Suppliers

Develop systematic approaches for locating and evaluating wholesale suppliers who demonstrate reliability, competitive pricing, and comprehensive inventory management capabilities for MWM components.

Supplier Verification Methods

Background checks and business verification form the foundation of supplier evaluation processes. Research company histories, financial stability, and market reputation through industry associations and trade references.

Established suppliers typically maintain transparent business practices and readily provide verification documentation. Online presence evaluation includes website professionalism, contact information accuracy, and customer testimonial authenticity.

Professional suppliers invest in comprehensive digital platforms showcasing inventory capabilities, technical specifications, and customer service resources. Social media engagement and industry participation indicate active market involvement.

Industry Certifications and Credentials

Quality management certifications such as ISO 9001 demonstrate systematic quality control processes throughout supplier operations. Industry-specific certifications validate technical expertise and commitment to maintaining professional standards. Certification maintenance requires ongoing auditing and improvement initiatives.

Professional memberships in automotive aftermarket associations indicate supplier commitment to industry best practices and ethical business conduct. Trade organization participation provides networking opportunities and access to continuing education resources that enhance supplier capabilities.

Geographic and Logistical Factors

Proximity considerations affect shipping costs, delivery timeframes, and emergency availability for critical MWM components. Regional suppliers offer advantages in urgent situations requiring immediate part delivery. International suppliers may provide cost benefits but require longer lead times and complex logistics coordination.

Distribution network capabilities determine inventory accessibility and shipping efficiency across different geographic regions. Established suppliers maintain strategic warehouse locations enabling rapid response to customer requirements while minimizing transportation expenses.

Evaluating Supplier Reliability

Implement comprehensive assessment criteria to determine supplier dependability, financial stability, and long-term partnership potential for sustainable MWM parts procurement strategies.

Track Record Assessment

Historical performance data reveals supplier consistency in delivery schedules, quality standards, and customer service responsiveness. Request customer references and conduct interviews with existing clients to gather firsthand experiences. Long-standing business relationships indicate supplier stability and reliability.

Performance metrics evaluation includes order accuracy rates, delivery timeframes, and defect percentages across extended periods. Consistent performance patterns demonstrate operational maturity and systematic quality control processes. Declining performance trends may indicate internal challenges requiring attention.

Financial Stability Indicators

Credit reports and financial statements provide insight into supplier financial health and operational sustainability. Stable suppliers demonstrate consistent revenue growth, manageable debt levels, and adequate working capital reserves. Financial instability risks include supply disruptions and potential business closure.

Payment terms and credit policies reflect supplier confidence in customer relationships and financial management practices. Flexible payment arrangements indicate strong financial positioning, while restrictive terms may suggest cash flow challenges requiring careful evaluation.

Customer Service Standards

Response times to inquiries demonstrate supplier commitment to customer satisfaction and technical support capabilities. Professional suppliers maintain knowledgeable staff capable of addressing technical questions and providing application guidance. Prompt communication indicates organizational efficiency and customer priority.

After-sales support services, including administration, return procedures, and technical assistance, differentiate professional suppliers from commodity vendors. Comprehensive support programs demonstrate long-term partnership commitment and operational sophistication.

Building Strategic Partnerships

Establish mutually beneficial relationships with reliable MWM parts wholesale suppliers through effective communication, clear expectations, and collaborative planning initiatives.

Negotiating Wholesale Terms

Volume commitments enable favorable pricing structures and priority allocation during supply constraints. Negotiate annual purchase agreements specifying minimum order quantities, delivery schedules, and pricing escalation clauses. Long-term commitments provide mutual benefits through predictable revenue and cost structures.

Payment terms negotiation balances cash flow requirements with supplier risk management needs. Early payment discounts may offset financing costs while extended terms improve working capital management. Clear payment procedures prevent misunderstandings and maintain positive relationships.

Inventory Management Coordination

Demand forecasting collaboration enables suppliers to optimize inventory levels and ensure product availability during peak demand periods. Share historical usage data and projected requirements to facilitate proactive inventory planning. Coordinated planning reduces stockout risks and minimizes carrying costs.

Consignment arrangements allow inventory access without immediate ownership transfer for high-value or slow-moving MWM components. Consignment programs require detailed tracking systems and clear ownership transfer protocols. Such arrangements benefit both parties through improved cash flow and inventory turnover.

Quality Assurance Protocols

Incoming inspection procedures verify component quality and specification compliance upon delivery. Establish sampling protocols and acceptance criteria, preventing defective parts from entering inventory systems. Document quality issues and collaborate on corrective action implementations.

Supplier quality audits evaluate manufacturing processes and quality control systems, ensuring consistent output standards. Regular audits maintain quality awareness and identify improvement opportunities. Collaborative quality initiatives strengthen partnerships and enhance customer satisfaction.

Frequently Asked Questions

What documentation should I request from MWM parts wholesale suppliers?

Request business licenses, quality certifications, insurance coverage, and customer references from potential suppliers. Verify ISO certifications, industry memberships, and financial stability through independent sources.

Documentation review ensures supplier legitimacy and operational capability before establishing business relationships.

How can I verify the authenticity of MWM parts from wholesale suppliers?

Authentic parts display proper part numbers, packaging, and quality markings consistent with MWM standards. Request certification documentation and compare specifications with official MWM publications.

Reputable suppliers like zuhonpower.com provide detailed authenticity verification and quality assurance documentation for all components.

What minimum order quantities should I expect from wholesale suppliers?

Minimum order quantities vary by supplier size, part categories, and market positioning strategies. Industrial suppliers typically require substantial minimum orders, while specialized distributors may offer more flexible arrangements. Negotiate terms based on your volume requirements and relationship development goals.

How do I handle quality issues with wholesale MWM parts suppliers?

Establish clear return procedures, quality standards, and communication protocols before placing orders. Document quality issues with photographs and detailed descriptions.

Professional suppliers provide rapid response and corrective action plans. Maintain detailed records supporting supplier performance evaluations.

Securing Your MWM Parts Supply Chain Success

Successful MWM parts wholesale sourcing demands systematic supplier evaluation, strategic relationship building, and ongoing performance monitoring. Invest time in thorough supplier verification processes, establish clear communication channels, and maintain detailed performance records.

Professional partnerships with reliable suppliers ensure consistent access to quality components while minimizing operational disruptions and maximizing cost efficiency for your business operations.