The TP welded plate heat exchangers are very useful nowadays. They are becoming popular in many countries. These machines help us to transfer heat from one fluid to another easily. They should be used properly and maintained regularly for their best working.

Many people think maintaining these heat exchangers is difficult. But if you know how to use it properly, it is very simple to operate. With some basic steps, you can keep your TP Welded Plate Heat Exchanger running smoothly for years.

What Makes These Heat Exchangers Special

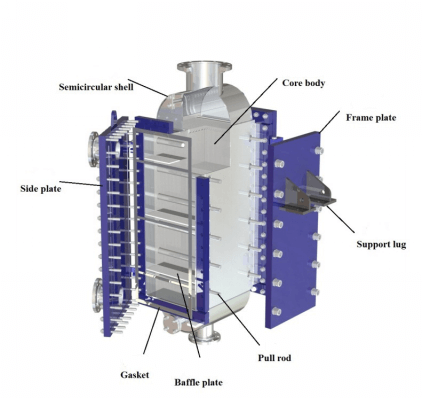

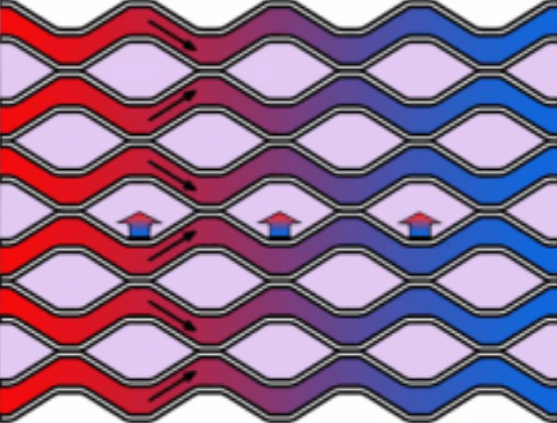

A TP Welded Plate Heat Exchanger is different from regular heat plate exchangers. everything is welded together. You don’t have to be upset by using rubber gaskets that can break. This heat exchanger solves this problem. It’s easy to operate. The welding makes the machine stronger and it wouldn’t leak.

The welded design means they can handle high pressure and temperature better. They also work well with harsh chemicals that might damage other types. Since there are no gaskets to replace, maintenance is easier in many ways.

The plates are permanently joined together. This creates a sealed system that doesn’t have the usual leaking problems. Most maintenance work focuses on the outside of the unit and keeping the fluids clean.

Simple Daily Checks

Start each day by taking a quick look at your heat exchanger. Walk around it and see if anything looks different. Also:

- Check leakage from pipes or joints.

- Listen to sounds that come from it while working.

- If it shakes more than usual, it could be a problem.

- Look at the pressure and temperature meters.

- Write down the readings each day to track changes.

- If today’s numbers are very different, check what’s wrong.

- Look closely at the pipes going in and out — they often show early signs of trouble.

A short daily check can help stop bigger problems later.

Keeping Fluids Clean

Clean fluids keep the heat exchanger working well. Hard water should not be used because it leaves deposits. These deposits make the exchanger less efficient. Test your water regularly and use softeners or other treatments to prevent this. It’ll save you money on repairs!

Watching Performance

Keep track of how well your welded heat exchanger is working. Simple measurements can tell you a lot about its condition. Temperature differences and pressure drops are good indicators.

When performance starts dropping, it usually means cleaning is needed. Don’t wait until performance gets really bad. Regular cleaning is easier and more effective than trying to fix heavy buildup.

Planning Maintenance

Set up a regular schedule for different maintenance tasks. Daily checks, weekly inspections, and periodic cleaning should all be planned. Having a schedule means nothing gets forgotten.The schedule depends on how your TP Welded Plate Heat Exchanger is used. Units handling dirty fluids or running at high temperatures need more frequent attention. Clean, mild applications need less maintenance.

Plan major cleaning during scheduled shutdowns when possible. This avoids disrupting production. Emergency cleaning is more expensive and disruptive than planned maintenance.Keep records of all maintenance work. Write down what was done and when. This information helps improve the maintenance schedule over time.

Solving Common Problems

Sometimes things go wrong despite good maintenance. Knowing what to look for helps solve problems quickly. Most issues have warning signs if you know what to watch for.Reduced heat transfer is usually the first sign of trouble. This often means buildup inside the unit is blocking heat transfer. Cleaning usually fixes this problem.

Higher pressure drop means something is restricting flow. This could be buildup, a partially blocked passage, or a valve problem. Check the obvious things first before assuming internal problems.External leaks are less common with welded units but can still happen. Check all connections first. If the leakage is from the welded point, then only a professional can repair it.

Getting Help When Needed

Some maintenance jobs are too tricky to do yourself. If you’re not sure, just call professionals – it’s better than breaking expensive equipment.

Why Get Professional Help

- Manufacturer Support: Equipment makers have good technical support. They know their products and give helpful advice. Keep their number handy.

- Professional Cleaning: For tough dirt or tricky jobs, cleaning services are smart. They have special tools and know-how to clean better than your staff.

- Expert Check-ups: Regular professional inspections find problems you might miss. Outside experts give you an honest look at your equipment.

Saving Money on Maintenance

Good maintenance doesn’t have to be expensive. Prevention costs less than fixing problems after they happen. Regular care extends equipment life and saves money long-term.

Buy cleaning chemicals and spare parts in reasonable quantities. Having supplies on hand prevents delays when maintenance is needed. But don’t buy more than you can use before they expire.

Train your staff properly on maintenance procedures. Well-trained people do better work and make fewer mistakes. Training costs are quickly recovered through better maintenance results.

Consider maintenance contracts for specialized work. Professional contracts can provide predictable costs and guaranteed service quality. They also free up your staff for other work.

Safety First

Always put safety first during maintenance work. Make Sure to:

- Wear the right safety things.

- Care extra while using cleaning chemicals.

- Turn off the equipment before starting any work.

- Lock power sources and stop all fluid flow.

- Double-check that the unit is fully shut down.

- Try to work in pairs, especially during chemical cleaning.

- Having a second person helps with safety and better results.

Making It All Work

Good maintenance of TP Welded Plate Heat Exchangers comes down to consistency and common sense. Regular attention prevents most problems. When issues do occur, quick action keeps them from getting worse.

Check it daily for some days. Using your more will help you understand it’s working better. TP Welded Plate Heat Exchanger is different, so adjust these tips to match your specific situation.

Think of maintenance as money well spent, not just an expense. Equipment that gets proper care works better and lasts much longer. It also breaks down less often. The time you spend on maintenance saves you money by avoiding bigger problems later.

When you take good care of your TP Welded Plate Heat Exchanger, it will work reliably for many years. These machines are built tough, but they still need regular attention to perform their best.