U.S. scientists have successfully discovered a new catalyst composed of four inexpensive metals using an innovative nanoscale chip technology. This catalyst can effectively replace the critical role of scarce and expensive iridium in green hydrogen production. This breakthrough is expected to reduce the cost of catalysts for electrolytic water splitting by 94%, offering a practical solution to one of the biggest bottlenecks in clean energy development.

High-Throughput Screening Technology

The research, a collaboration between Northwestern University and the Toyota Research Institute, utilized a nanomaterial chip platform called the “megalibrary” to conduct high-throughput screening of vast combinations of four metals: ruthenium, cobalt, manganese, and chromium. In record time, the researchers identified an optimal formulation (Ru₅₂Co₃₃Mn₉Cr₆ oxide) with catalytic performance comparable to or even surpassing that of commercial iridium-based materials.

“This is not only a breakthrough in materials science but also a milestone in clean energy development,” said the lead researcher. “For the first time, we have demonstrated that common metals, through precise formulation, can fully replace scarce precious metals to achieve highly efficient catalysis.”

The Iridium Challenge

Iridium is an extremely rare precious metal, with an abundance of only one part per billion in the Earth’s crust and an annual global production of just 7-8 tons. This silver-white metal offers exceptional corrosion resistance and high catalytic activity, making it indispensable as an oxygen evolution reaction catalyst in electrolytic hydrogen production. However, its extreme scarcity and high price of approximately $5,000 per ounce have severely hindered the large-scale commercialization of green hydrogen.

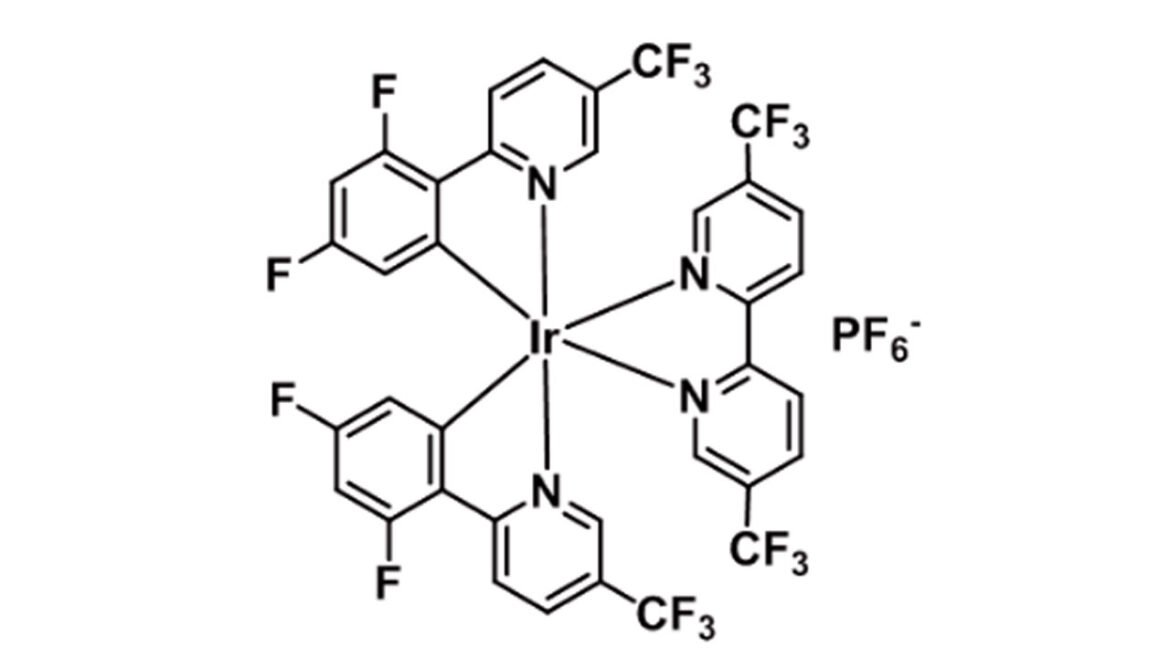

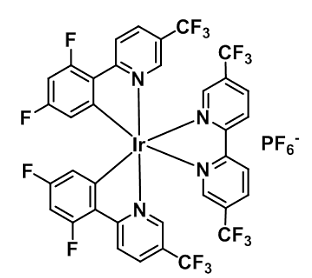

Metal Iridium Catalyst

Abundant and Affordable Alternatives

The research team turned their attention to four abundant and relatively low-cost metal elements:

- Ruthenium: As a platinum-group metal, ruthenium exhibits good catalytic performance. Priced at around $280 per ounce, it is still valuable but significantly cheaper than iridium. Global annual production is about 40 tons, primarily from Russia, South Africa, and South America.

- Cobalt: This silver-gray metal is widely used in batteries. Priced at approximately $20 per pound, its global annual production is about 170,000 tons, with the Democratic Republic of the Congo being the main producer. Cobalt offers excellent electrochemical properties.

- Manganese: As the fifth most abundant metal in the Earth’s crust, manganese is extremely affordable, priced at around $1,800 per ton. Global annual production exceeds 20 million tons, with widespread applications in the steel industry. Major producers include South Africa, Australia, and Gabon.

- Chromium: Primarily used in stainless steel production, chromium costs about $1 per pound. Global annual production exceeds 40 million tons, with South Africa, Kazakhstan, and India being the main suppliers.

Revolutionizing Materials Research

The researchers emphasized that the significance of this breakthrough extends far beyond the discovery of a single catalyst. The “megalibrary” technology establishes a new paradigm for materials research, enabling the synthesis and testing of millions of material combinations on a single chip, greatly accelerating the discovery of new materials. The high-quality datasets generated by this method provide a solid foundation for the application of artificial intelligence and machine learning in materials science.

Currently, the research team has successfully scaled up the new material and integrated it into devices to validate its feasibility. This technology not only paves the way for the large-scale and economical production of green hydrogen but also holds promise for accelerating the development of new materials in various fields, including batteries, biomedical devices, and optical components.