In industries with stringent hygiene requirements such as food, pharmaceutical, and bioengineering, the precision of flow control is as crucial as sanitary safety. Sanitary V-Port Ball Valves provide a reliable fluid control solution for these sensitive sectors, thanks to their specialized design philosophy and rigorous manufacturing standards. These valves not only inherit the precise regulating characteristics of industrial-grade V-Port ball valves but also meet the demanding requirements of sanitary applications in terms of material selection, surface finish, and structural design.

Sanitary V-Port Ball Valves

Sanitary V-Port Ball Valves are designed with an aseptic concept, featuring a structure that fully considers cleaning and sterilization needs. The valve inner cavity utilizes a large radius transition design, completely eliminating dead legs to ensure full drainage and prevent media retention. All wetted surfaces are precision polished to meet specified surface roughness requirements, effectively preventing microbial adhesion and growth. Furthermore, the valves employ quick-disconnect or aseptic connection designs, facilitating rapid disassembly and cleaning to meet the dual demands for efficiency and hygiene in modern production lines.

Excellent Control Performance

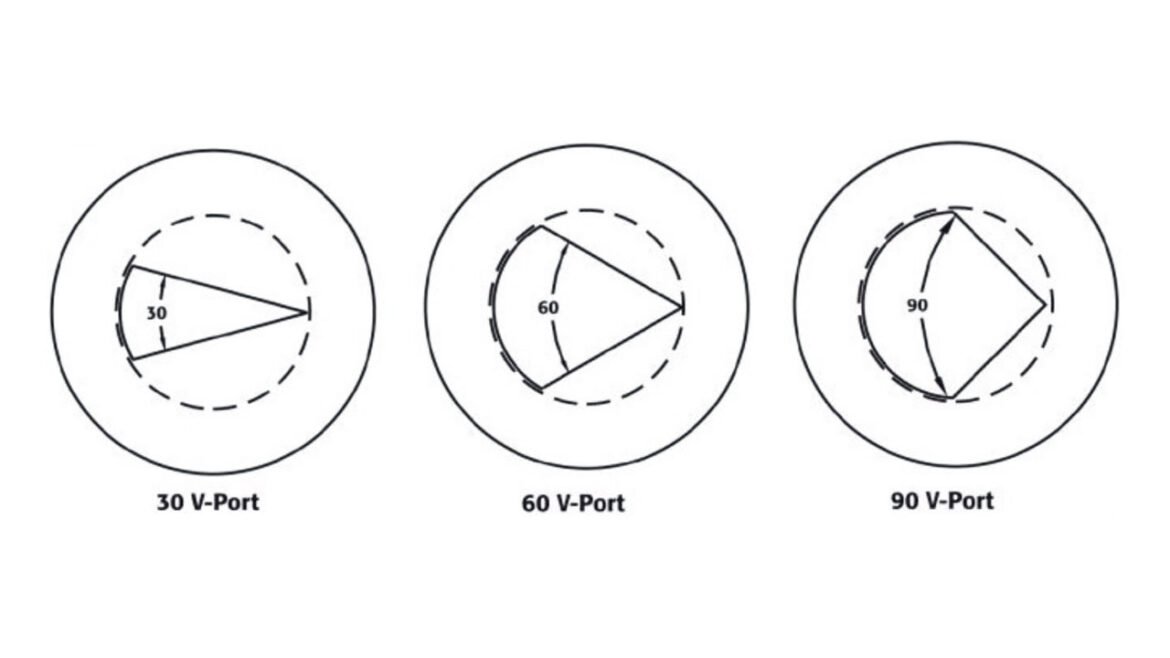

While maintaining precise flow control, Sanitary V-Port Ball Valves also address the specific needs of sanitary applications. The V-shaped notch design ensures linear flow regulation characteristics, enabling precise control from minimal flow to full flow. During the closing process, the sharp edge of the V-notch effectively shears fibers and particulates within the fluid, preventing media entrapment. The specialized sealing system not only guarantees zero leakage but also utilizes sealing materials that comply with food-grade or pharmaceutical-grade certifications, ensuring media purity.

Stringent Material Standards

Sanitary V-Port Ball Valves adhere to the strictest standards in material selection. All wetted components are made from 316L stainless steel or higher-grade materials, ensuring excellent corrosion resistance and chemical stability. Sealing materials typically include EPDM, PTFE, or silicone rubber compliant with standards such as FDA, USP Class VI, or EC1935/2004, ensuring stable performance during frequent CIP/SIP procedures. Material traceability and complete certification documentation provide strong assurance for the safe use of every valve.

Selecting the Right Sanitary V-Port Ball Valves

Selecting a Sanitary V-Port Ball Valve requires comprehensive consideration of multiple professional factors. First, confirm the characteristics of the process media, including viscosity, particulate content, and corrosiveness, to determine the appropriate valve specification. Next, choose the corresponding surface finish standards and connection types based on the required hygiene level of the process. Additionally, consider the cleaning and sterilization conditions, including the effects of temperature, pressure, and chemical agents, ensuring the valve materials can withstand all conditions encountered during the process.

Where to Order Custom Sanitary V-Port Ball Valves

After gaining an in-depth understanding of the characteristics of Sanitary V-Port Ball Valves, you might be looking for a trustworthy supplier. In the process industries, selecting a valve supplier is no minor matter; it directly impacts the reliable operation of production lines and the quality safety of the final product.

Among numerous valve manufacturers, Adamant Valves stands out for its expertise in the field of sanitary valves. As a leading enterprise focused on manufacturing high-standard valves, Adamant Valves is widely recognized for its exceptional sanitary valve solutions. They consistently use high-quality materials that meet international standards to create the most suitable Sanitary V-Port Ball Valve for each client. Adamant Valves offers comprehensive customization services, capable of providing fully personalized valve solutions tailored to your specific process requirements.

Final Thoughts

With their superior performance and reliable sanitary safety assurance, Sanitary V-Port Ball Valves have become the preferred solution in industries like food and beverage, pharmaceuticals, and bioengineering. They not only meet strict hygiene regulatory requirements but also ensure precise control and repeatability of production processes. As industry standards continue to rise and production technologies advance, Sanitary V-Port Ball Valves will continue to play an indispensable role in these critical sectors, providing robust support for product quality and production safety.