Press brakes are machines used in factories to bend metal sheets. They shape metal into parts for cars, buildings, and other items. If you work with metal, knowing the types of press brakes helps you pick the right one for your job. This article explains the main types in simple terms. We will cover how each type works, its good points, and where it fits best. By the end, you will understand which type might suit your needs.

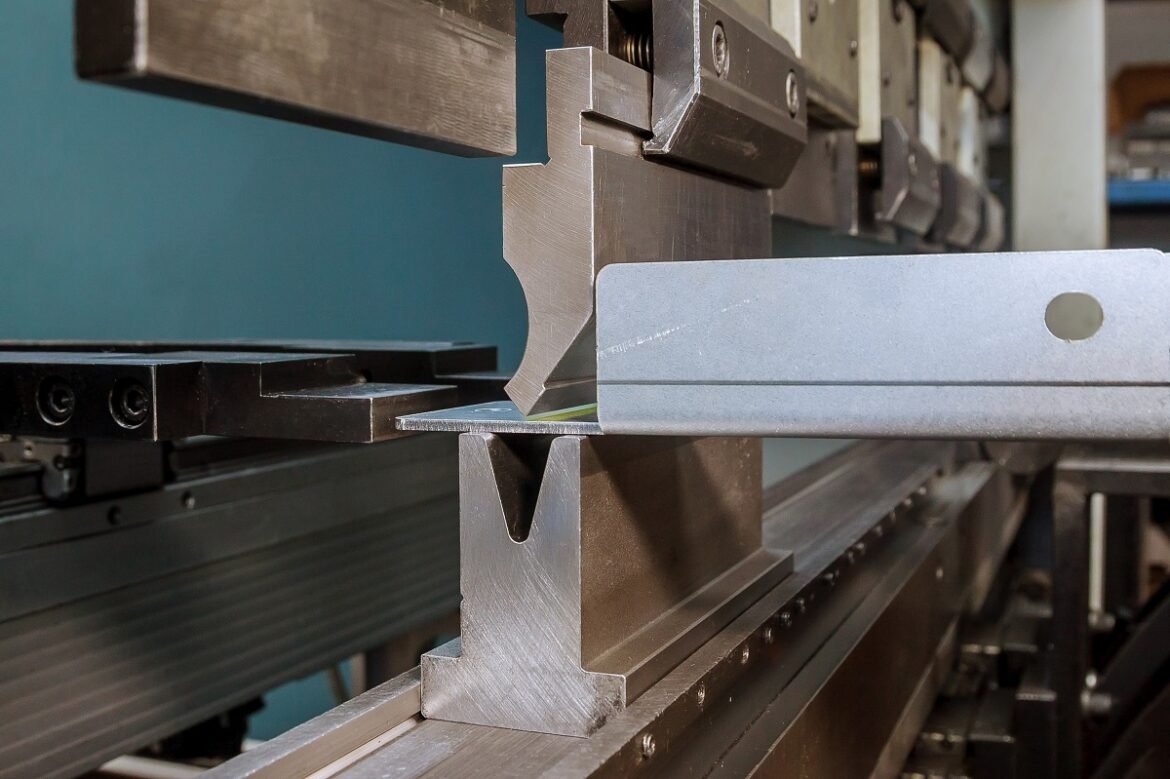

Press brakes come in different styles based on how they get power and control the bending. The basic idea is the same: a punch pushes the metal into a die to make a bend. But the way they do it changes with the type. Let’s look at each one step by step.

Mechanical Press Brakes

Mechanical press brakes are the oldest type. They use a flywheel and clutch to create force. When you start the machine, the flywheel spins fast. Then, the clutch connects it to the ram, which is the part that moves down to bend the metal.

These machines are strong and can bend thick metal quickly. They work well for jobs that need the same bend over and over, like making many identical parts. One good thing is they cost less to buy than newer types. They also run at high speeds, so you can finish work fast in a busy shop.

But they have some downsides. The force is hard to control precisely. Once the ram starts moving, it goes all the way down. You can’t stop it in the middle easily. This makes them less safe if something goes wrong. Also, they need regular checks on parts like the clutch and brakes to keep them running smooth.

In small shops or for simple tasks, mechanical press brakes are still popular. They handle materials like steel and aluminum up to certain thicknesses. If your work is basic and you want to save money, this type could be a good start.

Hydraulic Press Brakes

Hydraulic press brakes use oil and pumps to create force. Cylinders filled with oil push the ram down when you press a button or pedal. This type gives you more control over the speed and pressure.

One key benefit is safety. You can stop the ram at any point during the bend. This helps avoid mistakes and keeps workers safe. They also bend metal more accurately because you can adjust the force as needed. For example, if you work with thin sheets, you can use less pressure to avoid dents.

These machines are quiet compared to mechanical ones. They don’t have loud spinning parts. Maintenance is easier too, as you mainly check the oil levels and seals. They last longer in heavy use because the parts wear out slower.

Hydraulic models come in different sizes, from small ones for workshops to large ones for big factories. They handle a wide range of metals, including stainless steel. If you need flexibility in your bending jobs, this is a solid choice. For more details on options, check out this hydraulic press brake machine supplier.

Pneumatic Press Brakes

Pneumatic press brakes run on air pressure. They use compressed air to move the ram. This makes them light and easy to set up. You connect them to an air compressor, and they are ready to go.

These are best for light jobs. They work well with thin metal sheets where you don’t need a lot of force. Speed is a plus here; they bend quickly for small parts. They cost less to run because air is cheap compared to electricity or oil.

But they have limits. The force isn’t as strong as other types, so they can’t handle thick or hard metals. If the air pressure drops, the bends might not be even. You need a good compressor to keep the air steady.

In places like electronics factories or for making small brackets, pneumatic brakes shine. They are simple to use and don’t take much space. If your work involves light materials and high volume, consider this type.

Electric Press Brakes

Electric press brakes use motors and screws to move the ram. They are modern and energy-efficient. The motor turns a screw that pushes the ram down with exact control.

A big advantage is precision. You can set the bend angle to the exact degree needed. They use less power than hydraulic ones, which saves on bills. They also start and stop fast, making them good for quick jobs.

These machines are clean since there’s no oil to leak. Maintenance is low; you just check the motors and belts. They run quietly, which is nice in shared workspaces.

However, they might cost more upfront. They work best for medium-thickness metals. For very heavy work, they might not have enough power.

Electric models are growing in use for custom parts in industries like aerospace. If accuracy and low running costs matter to you, this type is worth looking at.

CNC Press Brakes

CNC press brakes stand for Computer Numerical Control. They are like the other types but with a computer brain. You program the bends on a screen, and the machine does them automatically.

This type combines the best of others. It can be hydraulic or electric underneath. The computer controls everything, from ram speed to back gauge position. This means fewer errors and faster setup for new jobs.

Benefits include repeatability. Once you program a part, every piece comes out the same. It’s great for complex shapes with multiple bends. Workers spend less time adjusting by hand.

The downside is the higher price. You need training to use the software. But over time, it saves money by reducing waste.

CNC brakes are common in auto parts and furniture making. They handle various metals and thicknesses. For high-tech shops, this is the go-to option.

In summary, the type of press brake you choose depends on your work. Mechanical for basic, fast jobs; hydraulic for control and safety; pneumatic for light tasks; electric for efficiency; and CNC for automation. Think about your budget, material, and volume.

To explore more, visit miharmle-cnc.com for a range of machines. Always match the type to your needs for the best results.